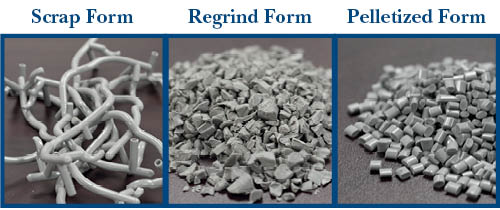

Pelletizing

Only high tech pelletizing equipment is used to form a perfect and uniform pellet. We understand the importance of moulding products using a clean, uniform and non-contaminated resin so only the best product will be provided to our customers.

When pelletizing using a regrind product, the resin is typically blended with other additives to make up a customer's specification. They will then be melted together in a machine called an 'Extruder'. The extruder has a screw that turns within and produces a 'strand' which will be cooled and cut into uniform pellets. The pellet will then be tested in a high tech lab to ensure it meets our customer's requirement.

The pellet will be ready to be used in any array of various products. It can be moulded into several types of automotive parts, drainage pipe, pails or even the refuse containers you take to the curb.

If you take a minute to look around the room you're sitting in right now, you'll be amazed to see just how many things are made from plastic. Reprocessing is an important part of our day to day life. It will make it a better place to live in the future.